Electric numerical control batch function features:

Electronic setting, torque, Angle, rotation speed can be set to any value

1. Each screw can set different tightening parameters (torque, Angle, speed, steering);

2. The tightening process of the same screw can be controlled by setting tightening parameters in sections to meet the requirements of highly complex tightening technology; After the completion of normal tightening, the single tightening process can increase torque maintenance reverse untwisting.

3. Effective tightening torque range can be set during single tightening process, parameter setting of Angle monitoring range can be added;

4. Torque control Angle control mode can be set separately.

Real-time counting error - - leak prevention control

1. The system has real-time counting function; The system will automatically reduce "1" once tightening is completed effectively.

2. External sensors can be added. When the screw is finished (missed) removed, the screwdriver will make an alarm sound; it doesn't work properly.

3, support signal input output function, joint fixture linkage with fixture to prevent staying. After the set amount is tightened effectively, the system can output the starting signal of the opening of the control jig to compulsively prevent screw leakage lock failure.

Iii. Tightening state control

1. When the torque reaches the corner too short, it can effectively detect the bad conditions such as missing screw washer, too short screw, screw floating lock screw defects.

2. When the torque reaches the corner too long, it can effectively detect the bad conditions such as too long screw, too much torque, screw sliding teeth, etc.

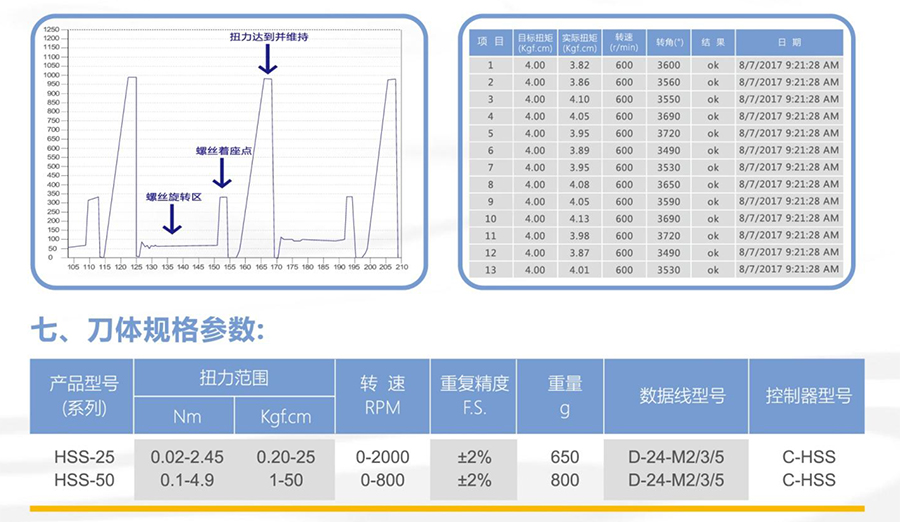

Iv. Visualization of tightening data

1. Online display of tightening data (torque Angle);

2. OK&NG displays the tightening state, prompts through color alarm.

5. Tightening curve analysis

1. The system supports PC link, which can generate the tightening process corresponding parameters curves;

2. Batch curves can be compared analyzed, relevant parameters curves can be generated;

Vi. Tightening data traceability

1. The system supports automatic storage of about 100,000 groups of data, which can be downloaded;

2. After linking PC, output can generate data table.

Viii. Control System Description:

1. Support barcode gun for product identification;

2. Support tightening state related signal output;

3. Support tightening data display, storage PC communication;

4. Support IO port communication of host computer, alarm lamp fixture;

5, support positive negative rotation, torque, speed, Angle of external start control

Tel:18025151318

Mai:service@jcuan.com

网址:www.jcuan.com

Company address: 3rd Floor, Building A, Kangpeng

Science park, No. 83, Yuanying Road, Zhuyuan Village,

Liaobu Town, Dongguan City

All rights reserved:Juchuan Assembly Automation Technology Co